Shop Now

- Warburtons Tool Kits

- Benches, Tools & Accessories

- Burs & Drills

- Casting & Melting

- Chains

- Cleaning

- Display

- Dust Extraction & Air Filtration

- FINDINGS - PEEKAYS

- Flex Shafts & Micromotors

- Forming

- Gemmological

- Gemstones

- Gift Voucher - Warburtons

- Jewellery Bead & Pearl

- Lapidary

- Lighting & Photography

- Magnifiers

- Mass Finishing

- Measuring: Gauges & Scales

- Metal: Sheet, Wire, Tube, Testing

- Microscopes

- Permanent Jewellery

- Plating, Colouring & Patinas

- Polishing & Abrasives

-

Presentation Packaging

- Carry Bags

- Carry Bags - Custom

- Deluxe Boxes

- Economy Jewellery Boxes

- Flock Boxes

- Imitation Leather

- Jewellery Pouches

-

Leatherette Jewellery Boxes

- Cufflink Box

- Gold Corner Earring Box

- Gold Corner Pendant Box

- Gold Corner Ring Box

- Gold Line Bangle Box

- Gold Line Bracelet Box

- Gold Line Earring Box

- Gold Line Necklace Box

- Gold Line Pendant Box

- Gold Line Ring Box

- Leatherette Bangle Box

- Leatherette Bracelet Box

- Leatherette Double Ring Box

- Leatherette Earring Box

- Leatherette Long Bracelet Box

- Leatherette Multi Box

- Leatherette Necklace Box

- Leatherette Pendant Box

- Leatherette Ring Box

- Silver Corner Earring Box

- Silver Corner Pendant Box

- Silver Corner Ring Box

- Plastic Bags & Shipping Boxes

- Repair Envelopes

- Ribbon

- Supplementary Parts

- Wood Jewellery Boxes

- Monthly Specials

- Clearance

- Reference Books, DVDs & Templates

- Safety

- Sandblasting

- Setting & Engraving

- Soldering & Welding

- Watchmakers

Which soldering board is right for you?

Soldering boards may seem like a fairly straightforward concept, however with jewellers’ needs being so diverse, it just makes sense to have the right board for each application.

G&A Warburtons have a great range of different soldering boards varying in size, material and price, to suit any jeweller’s individual needs and their budget.

Let’s take a look at all the different soldering boards available, their uses, and how to get the most out of them.

Non Asbestos Solder Board

First up and by far the best allrounder in the range, this board acts as a great foundation for most soldering, and its primary function is to protect your bench with its heat-resistant properties. It works best as a base for specific soldering boards, and while not the best board type to solder onto directly, it will work in a pinch. This square-shaped board comes in 150mm, 200mm and 300mm sizes, and offers the heat-resistance of asbestos without any of the associated health hazards! This is a great board type for any jeweller to have on hand, and if using it as a base for other boards, hot items won’t damage the table or workbench should they roll off onto this board. Hot pieces can also cool on this surface while you work on a more application-specific board.

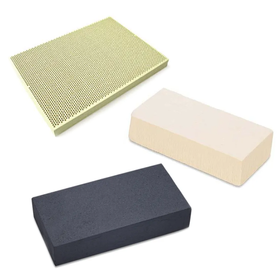

Refractory Soldering Brick

If the Non Asbestos Solder Board is the first recommended board for a jeweller just starting off, this board is the second! It has an operating temperature range of 900-1400 degrees C, and is also porous, meaning needles can be pressed into it easily. It can be sawed in half very comfortably with a normal hand saw; this second piece can then be folded back onto the first piece to give a reflective surface, so with cuffs or larger pieces for example, a user can reflect the heat back onto itself. The Soldering Brick is 220mm x 110mm x 30mm in size, and is another must-have for novice and experienced jewellers alike.

Honeycomb Ceramic Solder Board

This ceramic design is a very robust structure, and is not going to change form with use. The honeycomb style pattern works to trap heat and also reflect it back onto your piece, resulting in a very even heat around the flame, which is perfect for adhesion soldering. While not soft enough to push pins into the surface itself, the holes are sufficient for pins to be pressed into them to hold pieces in place. This board is 122mm x 80mm in size, and will withstand temperatures of up to 3000 degrees C.

Ceramic Solder Board

Once again this ceramic board is designed to handle high temperatures and offers a very flat surface for applications such as pendants and butt-joining, as well as soldering precious metals. This one is probably the go-to if you’re doing a lot of adhesion pieces with pendants, and comes in 150mm x 150mm and 300mm x 150mm sizes.

Soldering Block Soft Jig

Jewellers looking for a softer surface for working with odd shapes are catered for as well. This 120mm x 95mm x 40mm board is soft enough to push needles and wire through it to hold pieces in place, and it also deforms when objects are pressed against it, which will stabilise your piece. For example, if you pressed a dish into the Soft Jig and then hold it in place with needles & wire, you will have a very stable piece to work with. The Soft Jig has a working temperature of around 1200 degrees C.

Magnesium Solder Block

This is another great board for pinning, but is harder and denser than the Soft Jig. This key difference mens that when objects are pinned they will stay tight, which is great for applications such as claw setting. It also differs in size from the Soft Jig, coming in at 150mm x 73mm x 38mm. With a working temperature of around the 1200 degree C mark, similar to the Soft Jig, this is another really useful board to have in your kit, and an essential piece of kit if you’re planning on doing a lot of bracing and pinning.

Vermiculite Solder Board

As the name suggests, these boards are made from compressed vermiculite to hold their heat and increase soldering time. They are lightweight and soft in density, making them great for pinning. They are quite compact, so users won’t have to worry about stray fibers and dust that might occur with other boards. This board is great for anyone who wants a clean environment for their soldering, and comes in 330mm x 200 x 15 and 140mm x 70mm x 30mm sizes.

High Temperature Ceramic Solder Board

This board is fantastic for jewellers working with platinum and other high-end materials, and is comfortable working at temperatures at and beyond the 1800 degree C mark. At 220mm x 110mm x 20mm it will fit nicely inside your Non Asbestos Solder Board!

Charcoal Solder Block

This last soldering board is great for sterling silver with flat surfaces, and when heated it reflects heat back. Unique to this board is its ability to create a non-oxidising environment, which is important when working with sterling silver to prevent firescale. Firescale is where the surface of sterling silver oxidises and turns into a grey shadow, and this usually only becomes noticeable when polishing. The charcoal block actually sucks the air from around the flame, and prevents this process from occurring. The charcoal block will start to crack and break up with use, so it’s recommended to wrap some binding wire around it. This 140mm x 70mm x 30mm block will stay in shape even when it starts cracking. Another little tip with this board is to dip it in a bucket of water after use, as it can glow red-hot and hold its heat for a long time.